More precise - faster - more efficient

The first stubble processing after the harvest already forms the base for the following cultures. It disrupts the capillarity of the stubble and protects moisture reserves in the soil. The intensive incorporation as well as the subsequent consolidation grant a quick germination of drop out - grains and weed seeds, and therefore saves time and also increases overall profits. The TerraDiscPro meets these requirements perfectly: the form of the disc provides an outstanding mixing effect and good penetration of the soil, even in difficult soil conditions. This allows a higher working speed. A wide range of roller designs ensures optimal working results whatever the ground conditions. The TerraDiscPro also has huge clearances and the new frame construction ensures smooth work, even with large quantities of crop residues. The TerraDiscPro ensures a precise, quick & efficient work rate, even under extreme conditions.

Advanced Technology

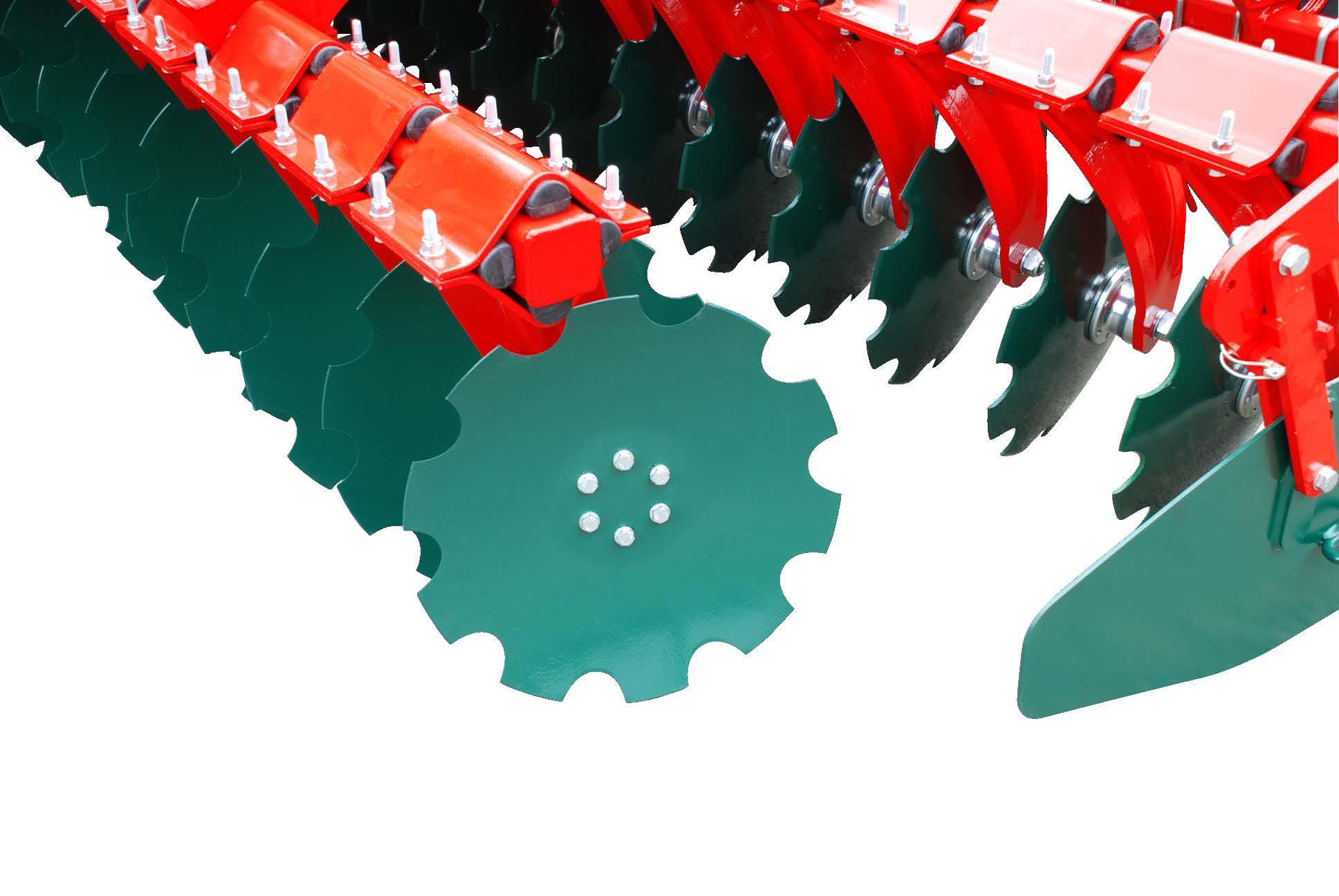

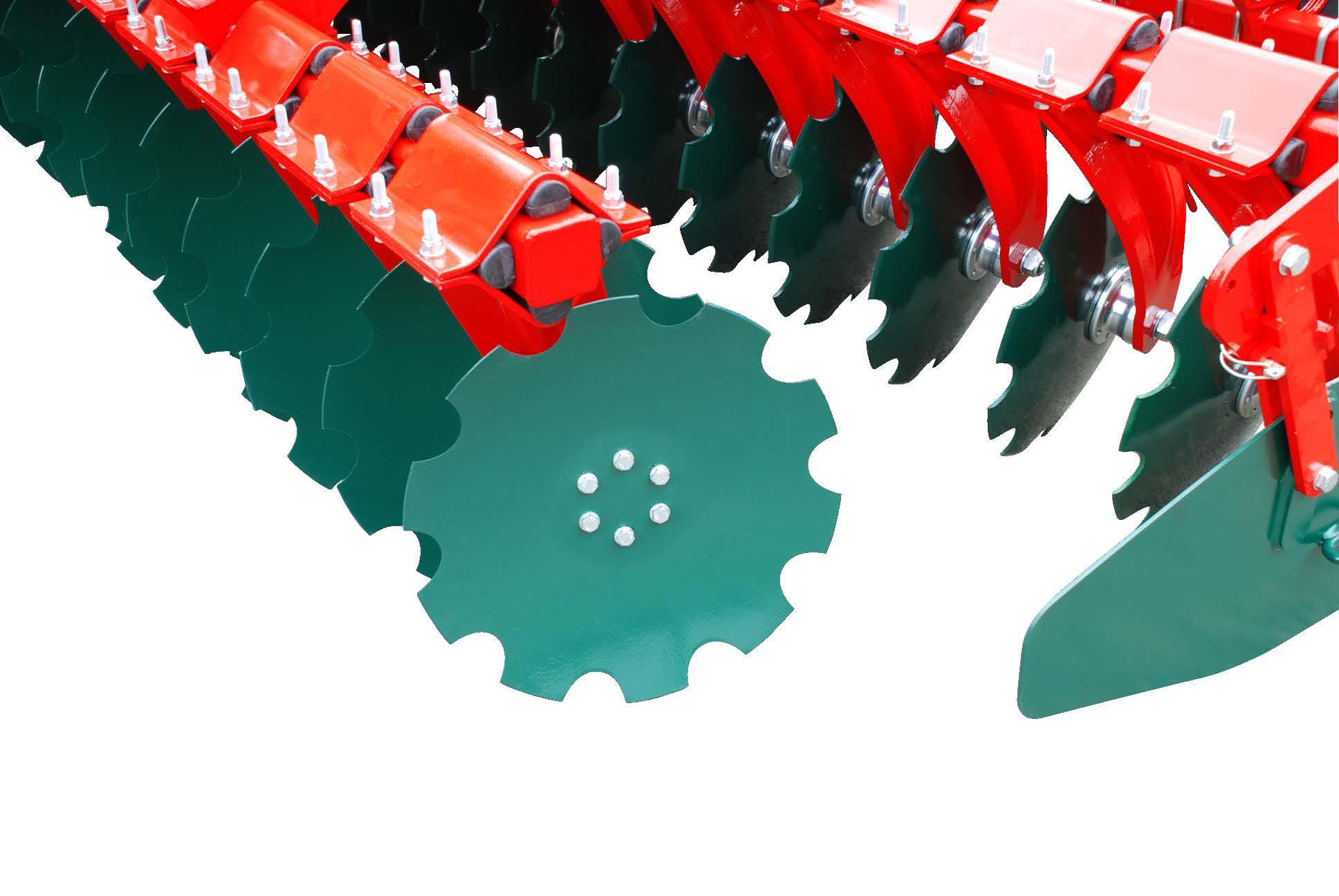

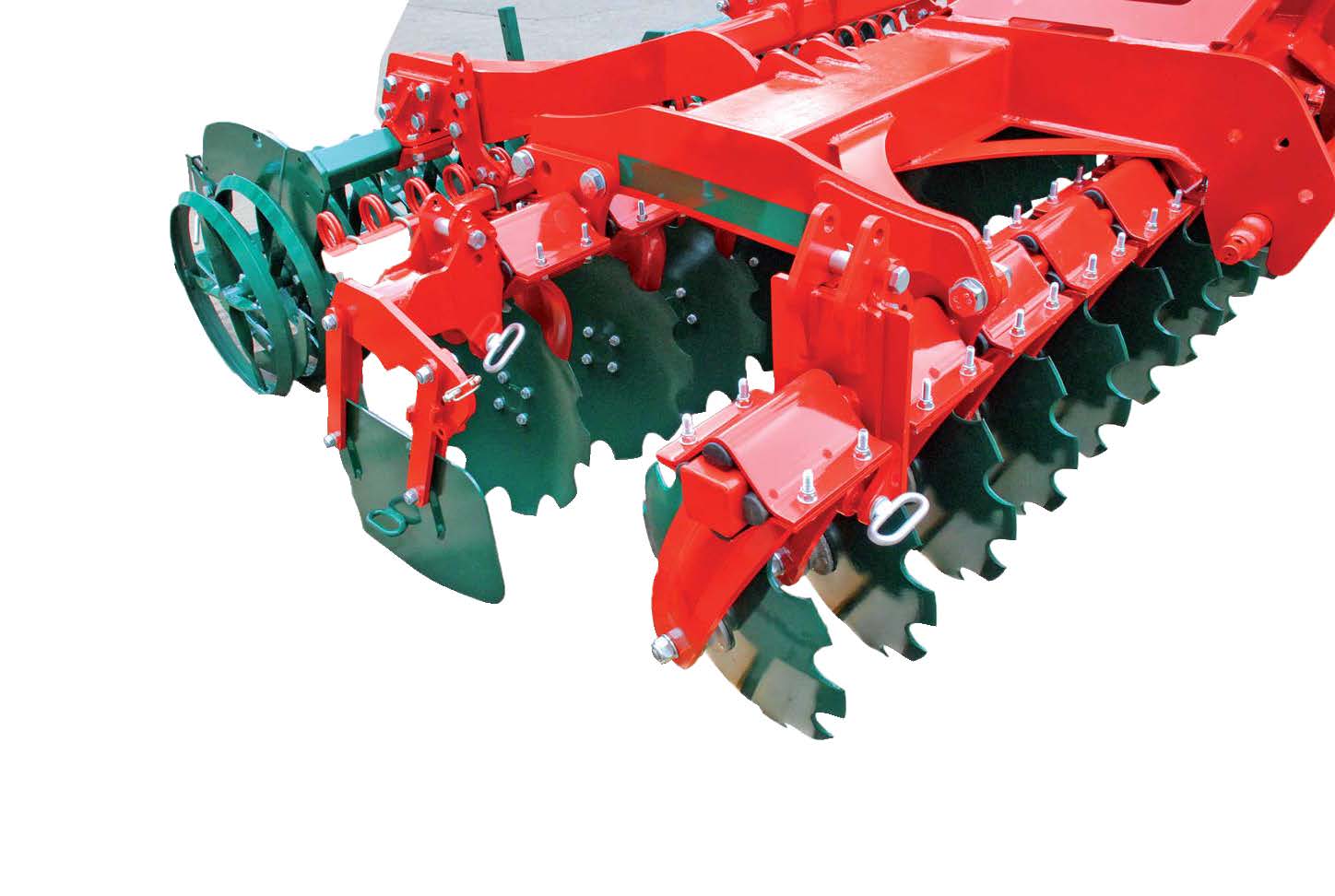

Toothed mulch-discs

The ideal dimensions of 510 mm diameter, as well as the special concave form of the discs, combined with the new intrusion angle ensure excellent penetration. This makes it possible to work in heavy and hard soils. Additionally, the good penetration enables higher working speeds, because the machine stays firm on the ground. The roughly rigged form supports this effect, and grants effective crumbling and optimal sprouting conditions.

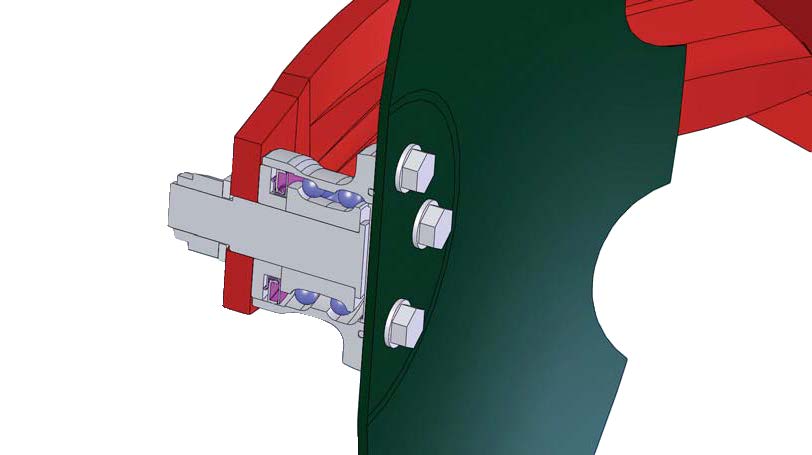

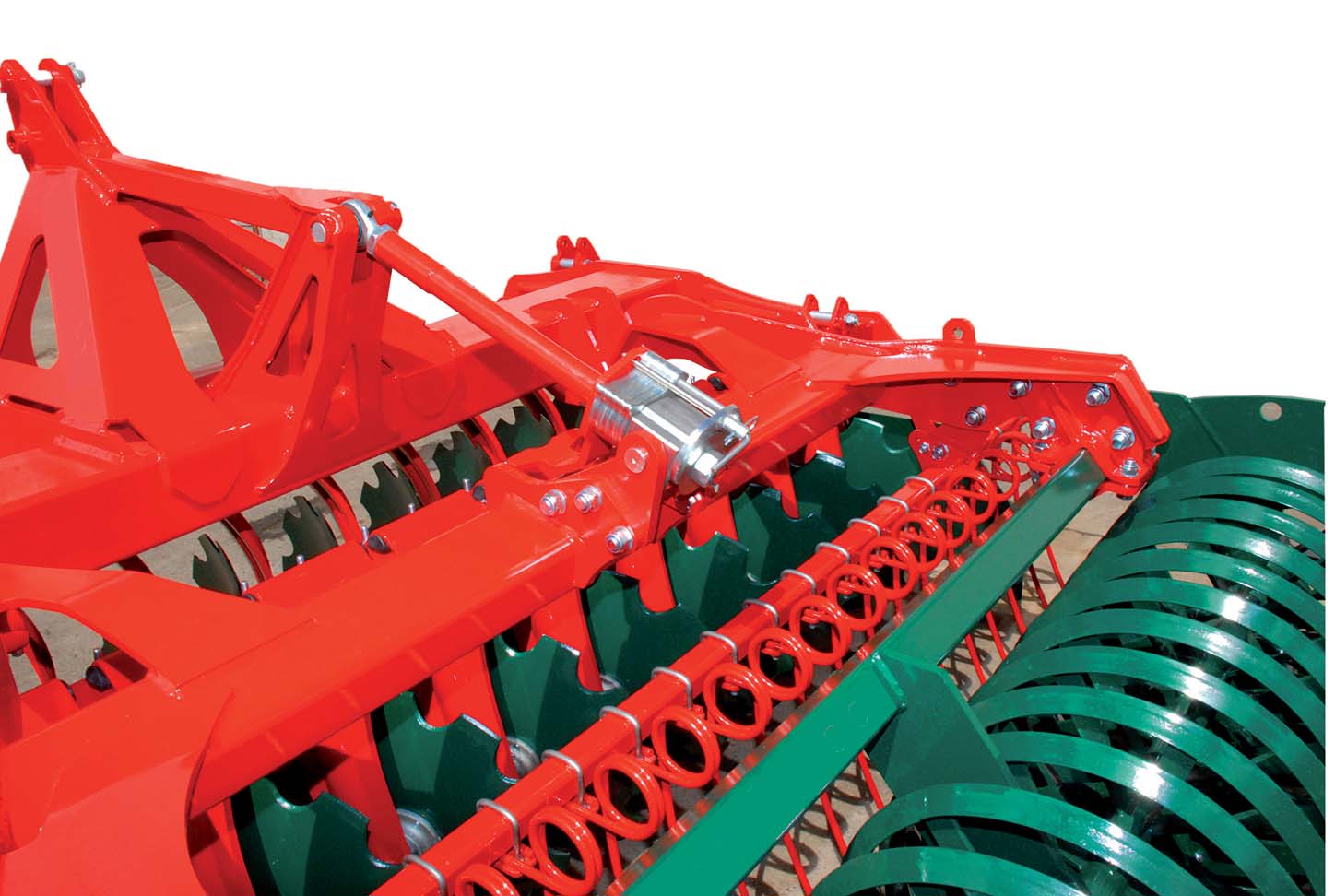

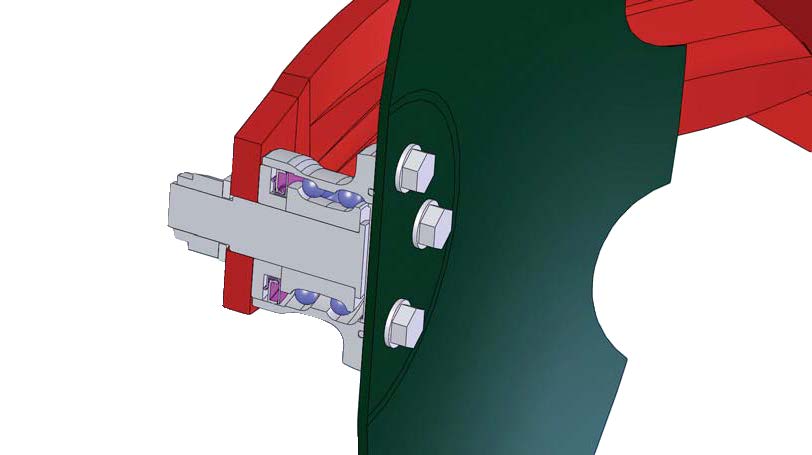

Flexible disc suspension

The installation of the rubber bushings on the discs ensures maintenance freedom and maximum operational reliability. These spring elements provide excellent soil adaptation with low-depth work and allow work on uneven ground or roadways. In addition, these rubber elements provide effective protection against overload on rocky soils.

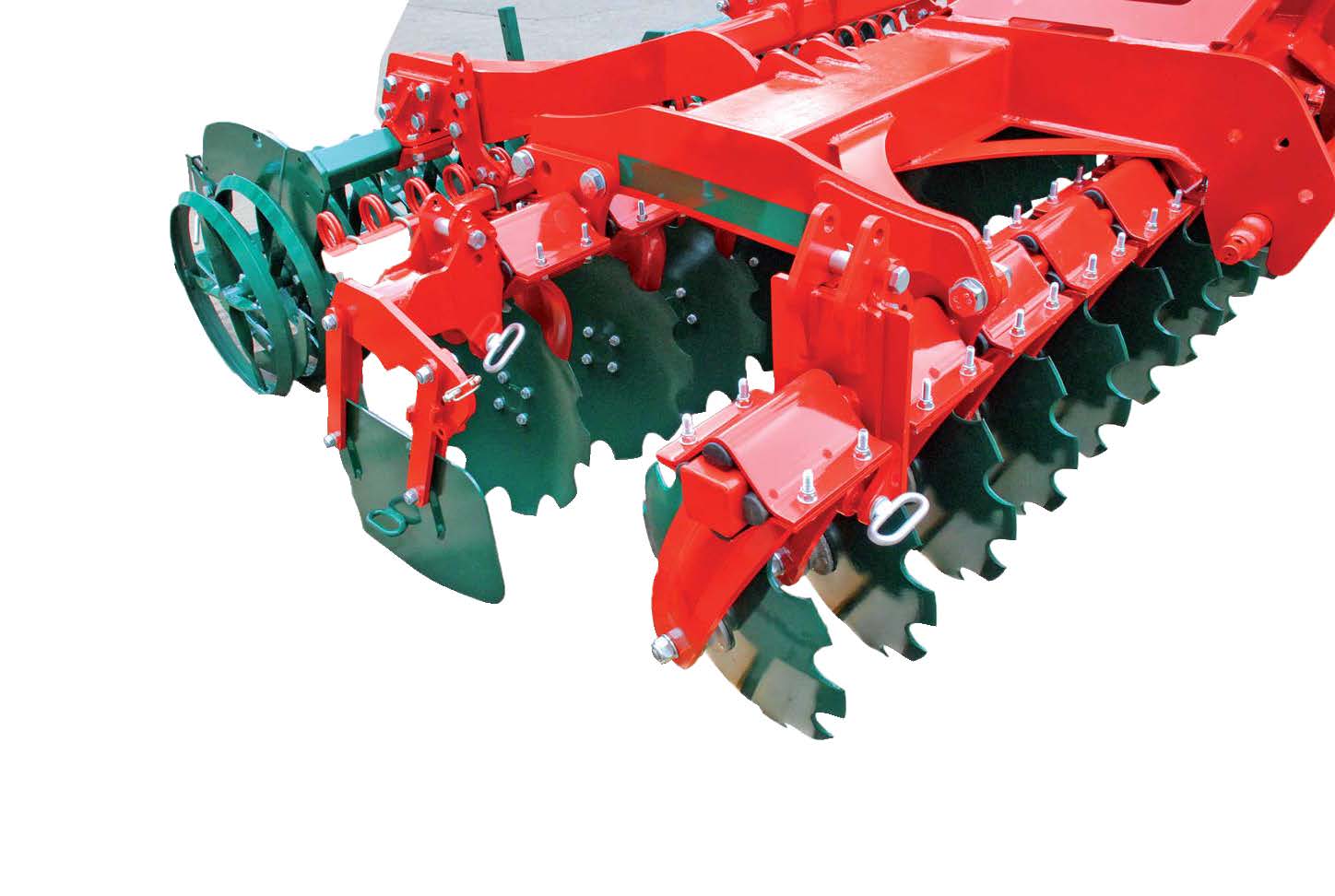

Effective working width - foldable edge discs

The nominal working width is achieved by the overlap of only one disc; this prevents partially worked strips at the edge of the field. The new spring-loaded edge discs can be folded fast and effortlessly, ensuring a width of less than 3.00 m for the device or 3.50/4.00 m (rigid devices) for secure road transport.

Disc bearings

The new TerraDiscpro is equipped with high-quality SKF-bearings only. The two-rowed maintenance-free corner bearings are tripple-sealed and continuously greased, so moisture and dirt don´t stand a chance. The screwed attachment of the bearing shaft to the disc holder greatly improves maintenance convenience immensely and avoids unnecessary repair costs.

Edge plates (optional)

The edge plates can, in certain situations, prevent ridges by the outer discs, thus ensuring a perfect connection between the different working widths. As with the edge discs, the edge plates are fast and effortlessly foldable and ensure a transport width of less than 3,00 m alternatively 3,50 / 4,00 m (fixed machines).

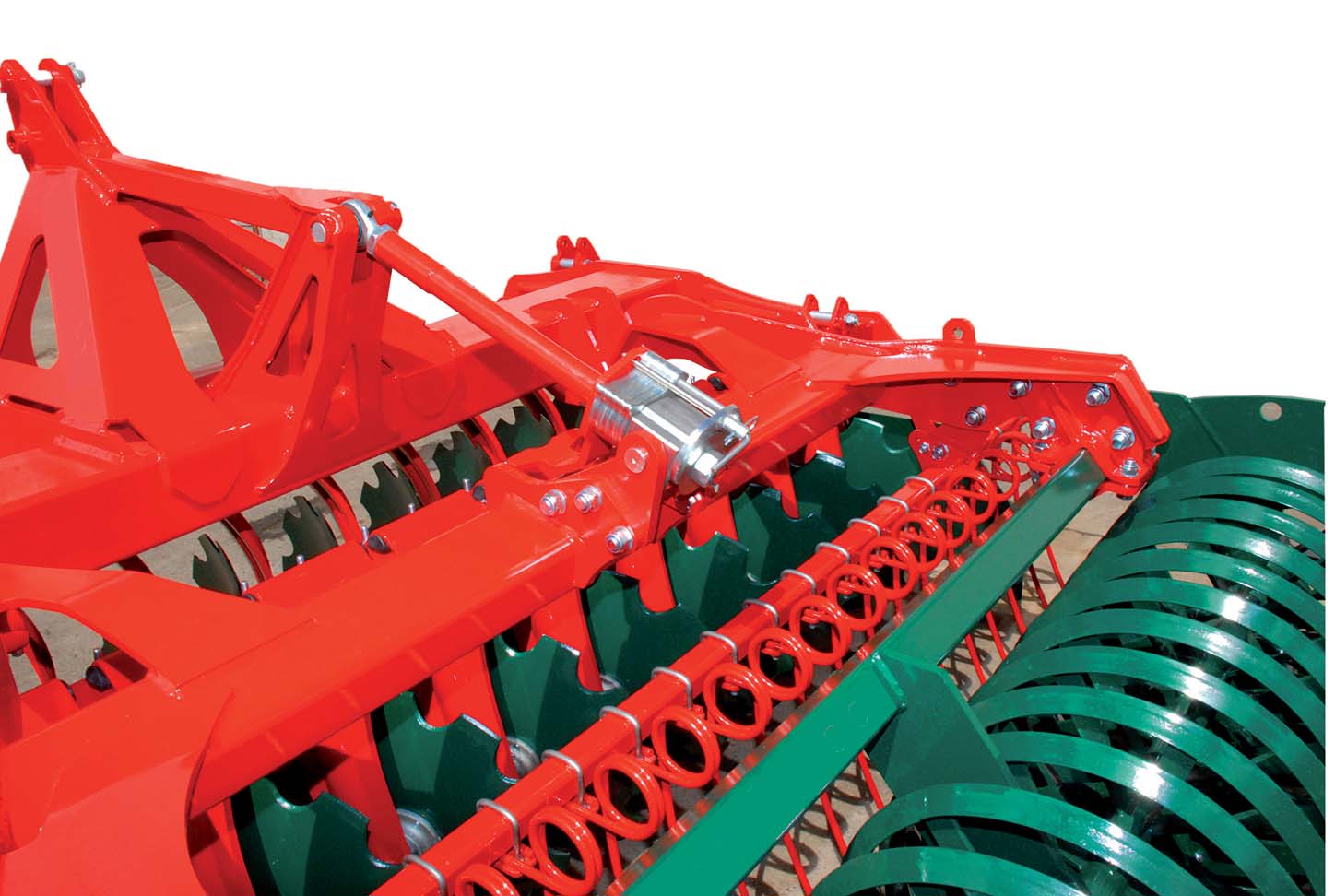

Working depth adjustment

The mechanical adjustment of the working depth is very comfortable and precise from the rear of the device with a central adjustment element with depth gauges that can be folded in and out. It is also possible to opt for hydraulic depth adjustment (for TerraDiscPro TR series with memory cylinder) which allows the operating depth to be adjusted over the whole range during operation, which is very advantageous, e.g. for temporary changes in depth for complete operation of ruts.

Rollers

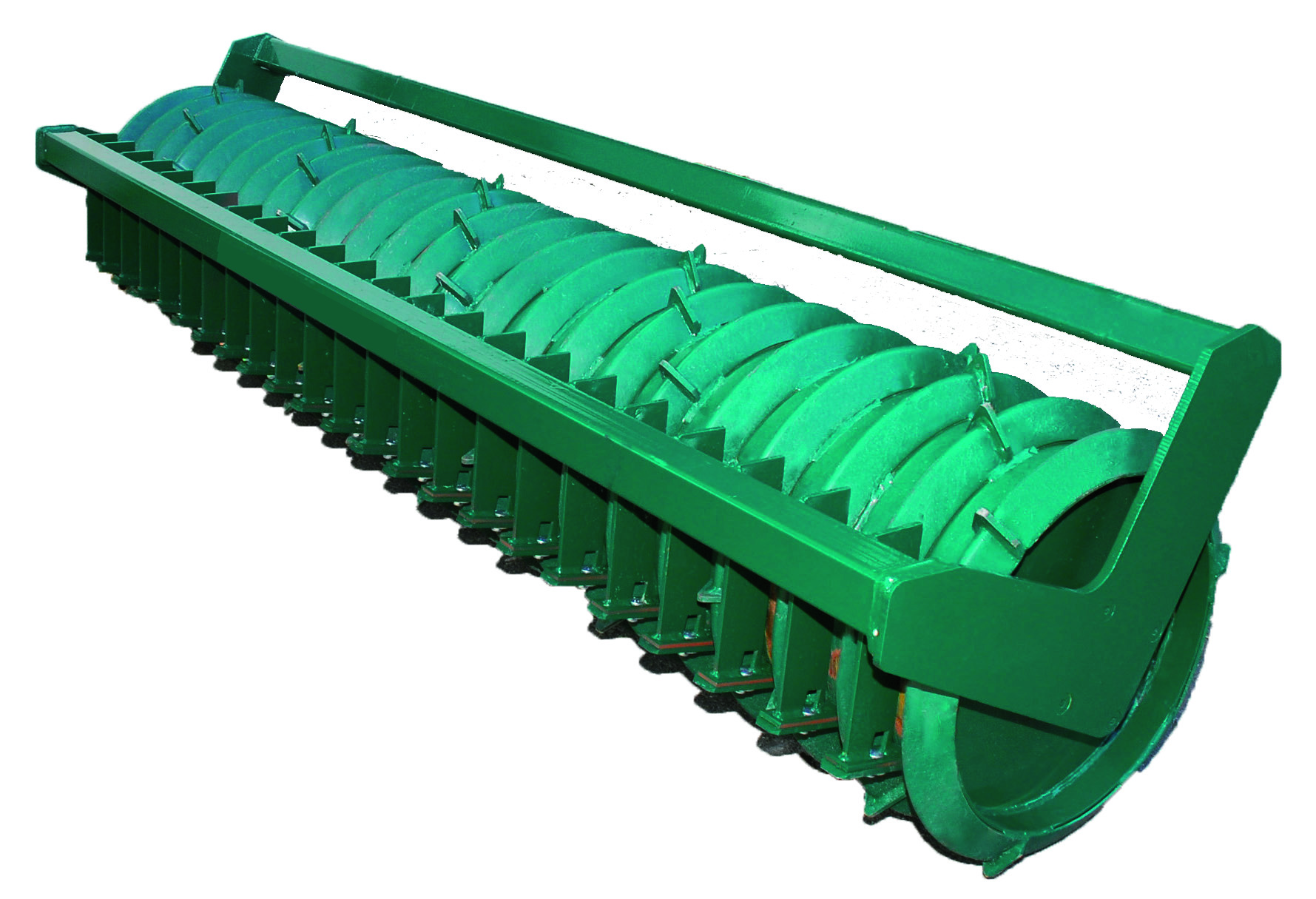

Toothed packer roller

Ø 520 mm - Ø 600 mm

• Good all-round features

• Particularly clog-resistant, thanks to scraper

• Tough in stony conditions

• Excellent ground drive with individually welded teeth

Open roller

Ø 520 mm

• Weight advantage: high bearing capacity on light to medium-heavy soils (10 rods)

• Arrangement of supporting V-bars (from 2 m) in order to avoid soil erosion and tension on the sides

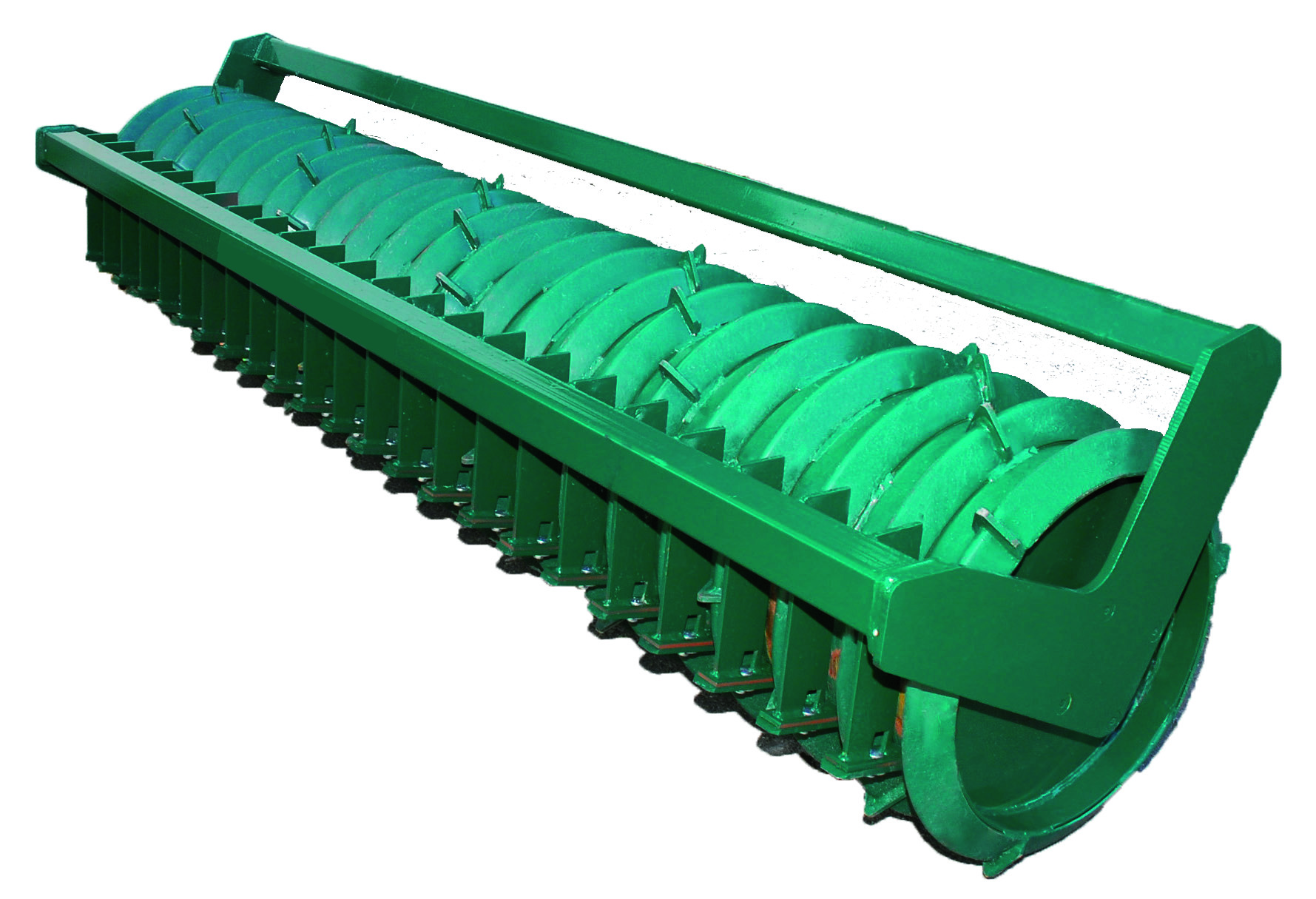

Solpak I ring roller

Ø 600 mm

• Ensures perfect leveling, compresses and closes soil

• The runners between the rings are height-adjustable, thus supporting the consolidation intensity. They also offer reliable cleaning of the rollers

• Particularly suitable for subsequent mulch sowing

Solpak II ring roller

Ø 600 mm

• Perfect work results with outstanding reconsolidation, crumbling and levelling

• Better ground drive in light conditions

• Greater stability with continuous central pipe and 5 spokes

• Improved ease of adjusting the scraper bar thanks to adjustment of only 1 spindle

Packer roller

Ø 800 mm

• High load capacity in light soils, the roller does not "sink"

• Very good ground drive thanks to angular shoulder profile, high degree of operational reliability

• Reconsolidation in distinct strips

• Highly suitable for subsequent mulch sowing

• No risk of blockages by stones

KTW roller

Ø 660 mm

• High loading capacity in light soils

• Good ground drive also in light and sandy grounds

• Tough in stony conditions

• High consolidation

• Grooved consolidation, highly suitable for subsequent mulch sowing

Tandem ring roller

Ø 600/600 mm

• Particularly viable in light, sandy soil

• Flat profiled discs arranged in 2 rows

• Excellent ground drive with individually welded driving plates

• Can be combined with TerraDiscPro with semi-trailed chassis

• Tracking tine (optional) for perfect levelling

Double open roller

Ø 520/440 mm

• Good leveling and very high load bearing capacity in heavy duty applications in light soil

• Arrangement of supporting V-bars (starting from 2 m) in order to avoid soil erosion and tension to the sides

* These pictures are for illustrative purposes only.

Harrow tines

Harrow tine in front of roller (optional)

The harrow tine which is located between the discs and the roller, guides the soil/straw mass away from the roller and downwards, thus ensuring perfect straw distribution. Recommended for open rollers like the SolPak-rollers.

Harrow tine behind roller (optional)

All rollers are also available with a harrow tine behind. With 12 mm thick tines, which are adjustable in tilting and height, the harrow ensures optimal alignment of the straw, and prevents quick growth of weeds. (Not available for TerraDiscPro TR models)